Discover flexible automation

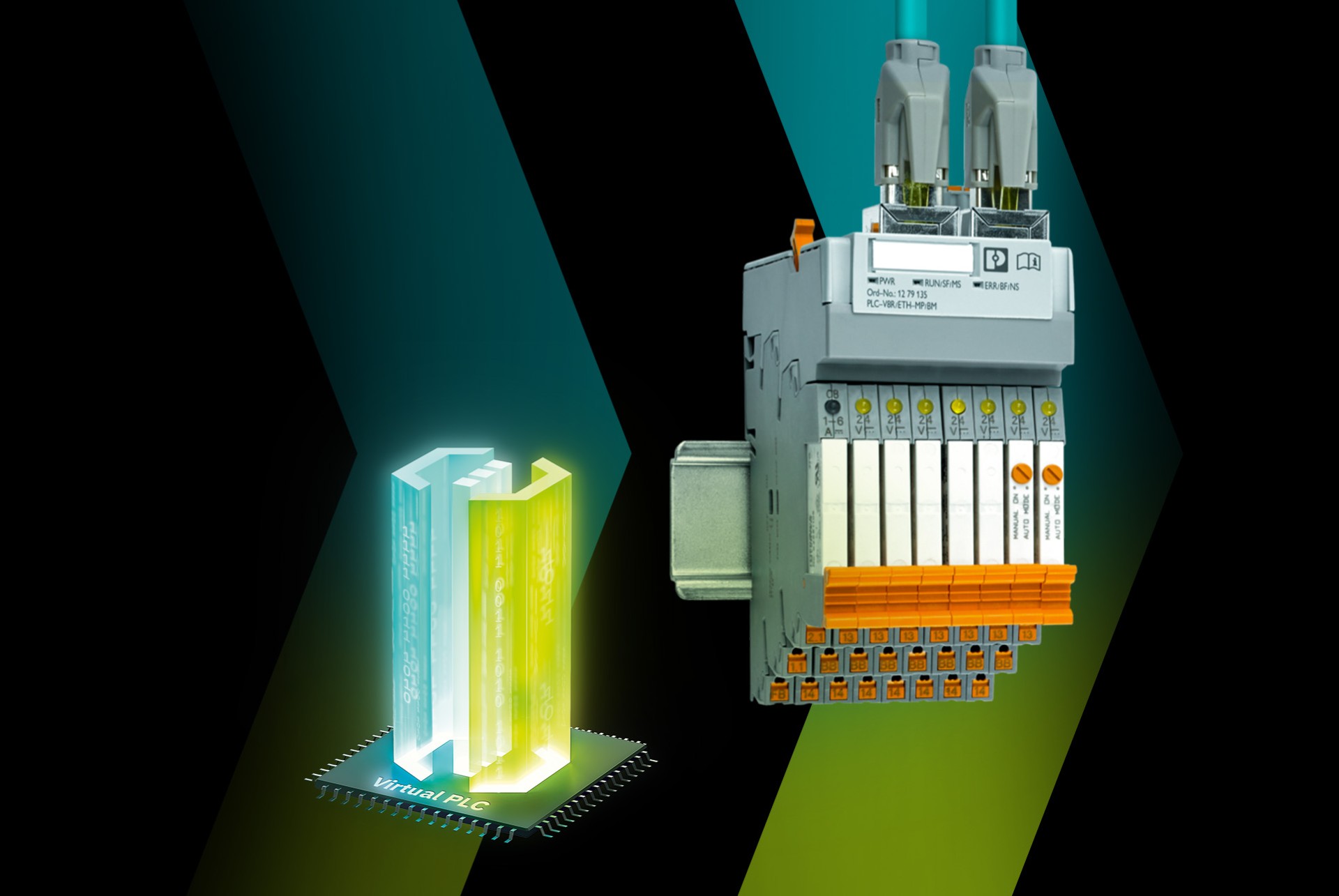

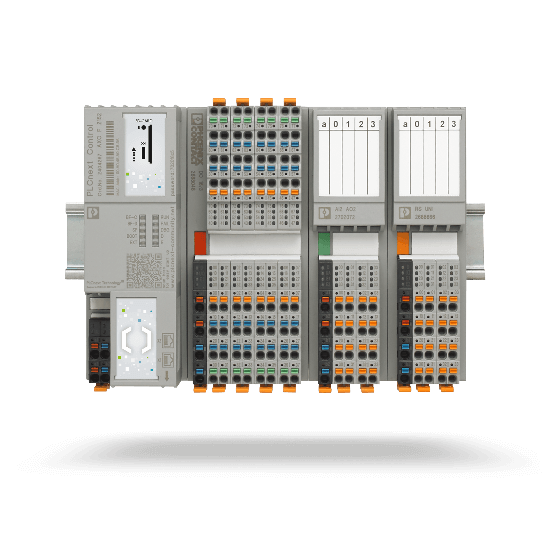

PLCnext Control

PLCnext Control are the hardware for the ecosystem PLCnext Technology. They allow to realize automation projects without the limitations of proprietary systems. The PLCs, based on a Linux kernel, are characterized by their real-time capability for IEC 61131-3 as well as for high-level languages such as C/C++ and Matlab®/Simulink®. The patented task handling allows any combination of IEC 61131-3 code, high-level languages and model-based tools in one task.

Connect directly to Proficloud or any other cloud and integrate individual cloud services. Use the data from your plant to optimize processes. In this way, you increase the quality of your products, reduce costs and do not have to intervene in running systems. Your data is perfectly protected because PLCnext Control is secure by design according to IEC 62443.

PLCnext Technology offers scalable controllers with IP20 protection. From modular controllers for basic applications to centrally managed high-performance controllers and PC-based edge devices, this product family always offers a suitable solution for your project. With the modular controllers you are very flexible in your station design. Choose from a wide range of I/Os or expand the functionality of the controller by adding modules on the left-hand side. If you want to implement AI or edge applications, our portfolio also offers optimized hardware for that. New technologies such as OPC UA, TSN and 5G can also be integrated thanks to the open Linux core. Thus, PLCnext Control offers highest future proofness.

Your advantages

- PLC-typical real-time performance and data consistency, also for high-level languages and model-based code

- Open Linux operating system

- Limitless adaption capability through quick, simple integration of open source software, apps, and future technologies

- Intelligent networking through cloud connection and integration of current and future communication standards

- PLCs in different performance classes enable ideal adaptation to your automation task

Controller

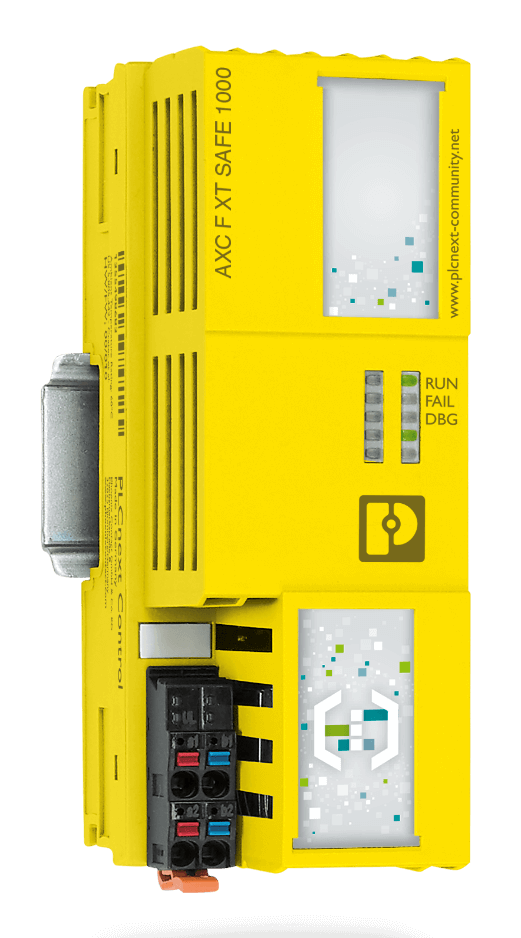

PLCnext Control Secure by Design

The controllers PLCnext Control AXC F 1152, AXC F 2152 and AXC F 3152 are the first PLCs to be certified by TÜV Süd in accordance with IEC 62443-4-1 ML 3 Full Process Profile in combination with IEC 62443-4-2. This confirms that the Secure Development Life Cycle was fully applied in the development of PLCnext Control. The product certification according to IEC 62443-4-1/-4-2 shows you that a product has been developed safely and provides information about which technical safety requirements have been implemented. By activating the safety profile, you also have access to an extensive range of safety level 2 (SL2) functions. The security is based on a Trusted Platform Module (TPM), on which user certificates can also be stored.

- Arm® Cortex® A9 single core, 800 MHz

- Up to 8 tasks

- Up to 16 PROFINET devices

- Up to 63 Axioline I/O modules can be aligned directly

- Trusted Platform Module (TPM) for security

- TÜV Rheinland certified in accordance with IEC 62443-4-1 ML 3 (Full Process Profile) and IEC 62443-4-2 SL-C 2

- M2M system networking with OPC UA

- Arm® Cortex® A9 dual core, 2x 800 MHz

- Up to 32 tasks

- Up to 64 PROFINET devices

- Up to 63 Axioline I/O modules

- Left-alignable interface extension

- Trusted Platform Module (TPM) for security

- TÜV Rheinland certified in accordance with IEC 62443-4-1 ML 3 (Full Process Profile) and IEC 62443-4-2 SL-C 2

- M2M system networking with OPC UA

- Intel® Atom™ E3930 dual core, 2x 1.3 GHz

- Integrated UPS

- Up to 128 PROFINET devices

- Ready for time-sensitive networking

- Up to 63 Axioline I/O modules

- Left-alignable interface extension

- Trusted Platform Module (TPM) for security

- TÜV Rheinland certified in accordance with IEC 62443-4-1 ML 3 (Full Process Profile) and IEC 62443-4-2 SL-C 2

- M2M system networking with OPC UA

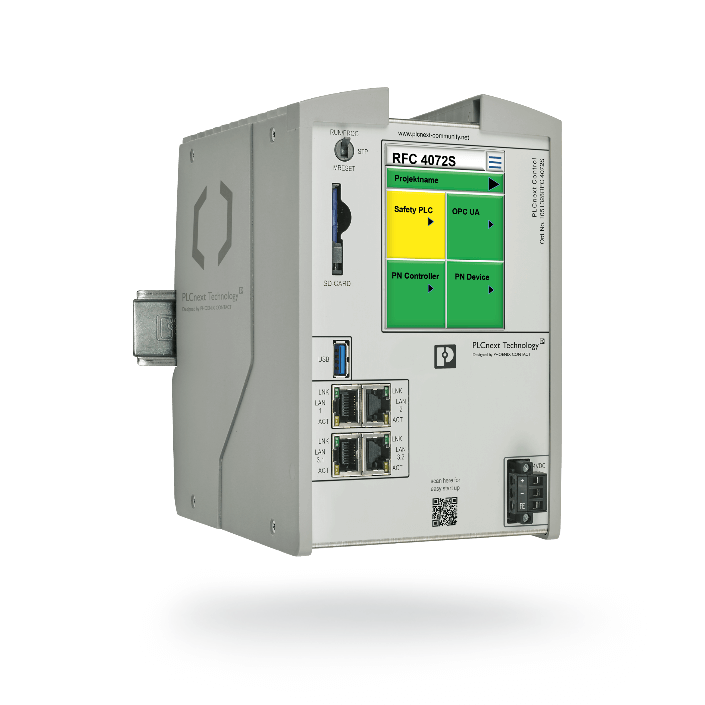

- PROFINET controller and device

- Support for PROFIsafe Profile V2.6.1

- Standard CPU: Intel® Core™ 5-6300U (dual core, 2.4 GHz)

- Safety CPU: 1 x ARM® Cortex® A9, 800 MHz & 1 x ARM® Cortex® A8, 600 MHz

- M2M system networking with OPC UA

- Standard and safety programming with PLCnext Engineer

- TÜV Rheinland certified in accordance with IEC 62443-4-1 ML 3 (Full Process Profile) and IEC 62443-4-2 SL-C 2

- Intel i5 6300U 2x 2.4 GHz processor

- 8 GB DDR 4 dual channel RAM

- 2 x 1 Gbit, 1 x 100 Mbit switched

- Synchronization interface SFP based

- Power supply: Dual interface

- 0°C – 55°C

- Intel Atom® x6413E (Quad Core, 1.5–2.4 GHz)

- Working memory: 16 GB RAM

- -20°C – 60°C

- Storage: 240 GB SSD

- Approvals: CE, UL

- Operating system: Ubuntu Pro Desktop

- Integrated DisplayPort, 2× USB, 2× COM (RS232/422/485)

- Pre-installed Virtual PLCnext Control

- Octa-Core Intel Core™ i7-10700TE

- ESM: Eight tasks simultaneously executed

- -20°C – 60°C (without optional fan)

- MTBF: 10 years without fan (25 years with optional fan)

- Vibration: Extended (3G)

- TSN ready

- TÜV Rheinland certified in accordance with IEC 62443-4-1 ML 3 (Full Process Profile) and IEC 62443-4-2 SL-C 2

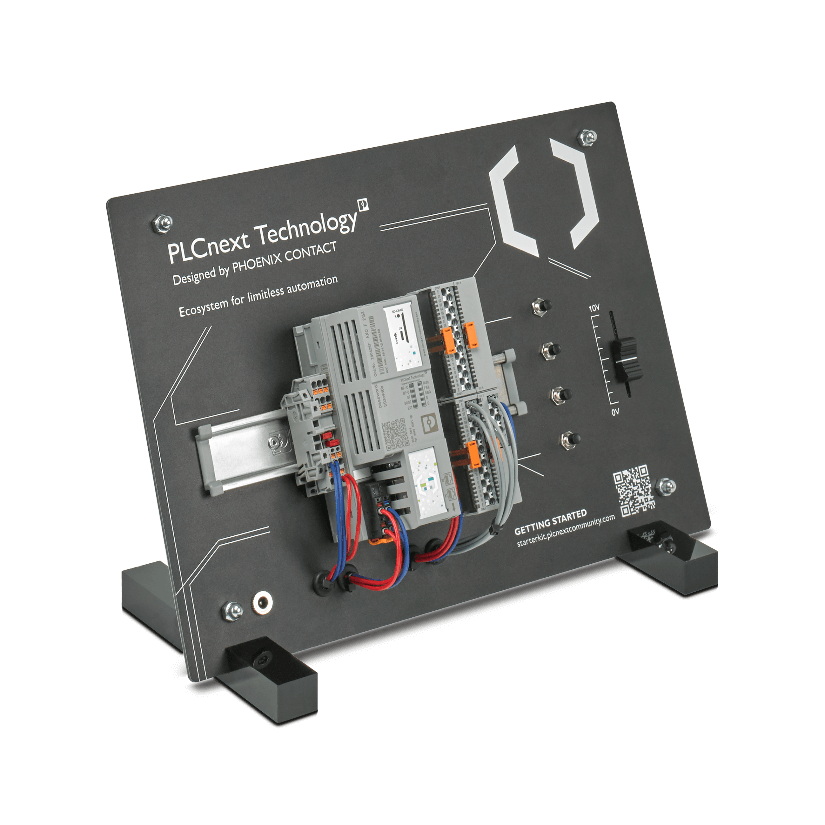

Do you want to try out the operation, handling, and performance of PLCnext Technology in a small-scale application first? This starterkit includes:

- PLCnext Control AXC F 2152

- Axioline Smart Elements: digital input, digital output, analog voltage input 0-10V

- 24V power supply unit

- Space for extensions on DIN rail

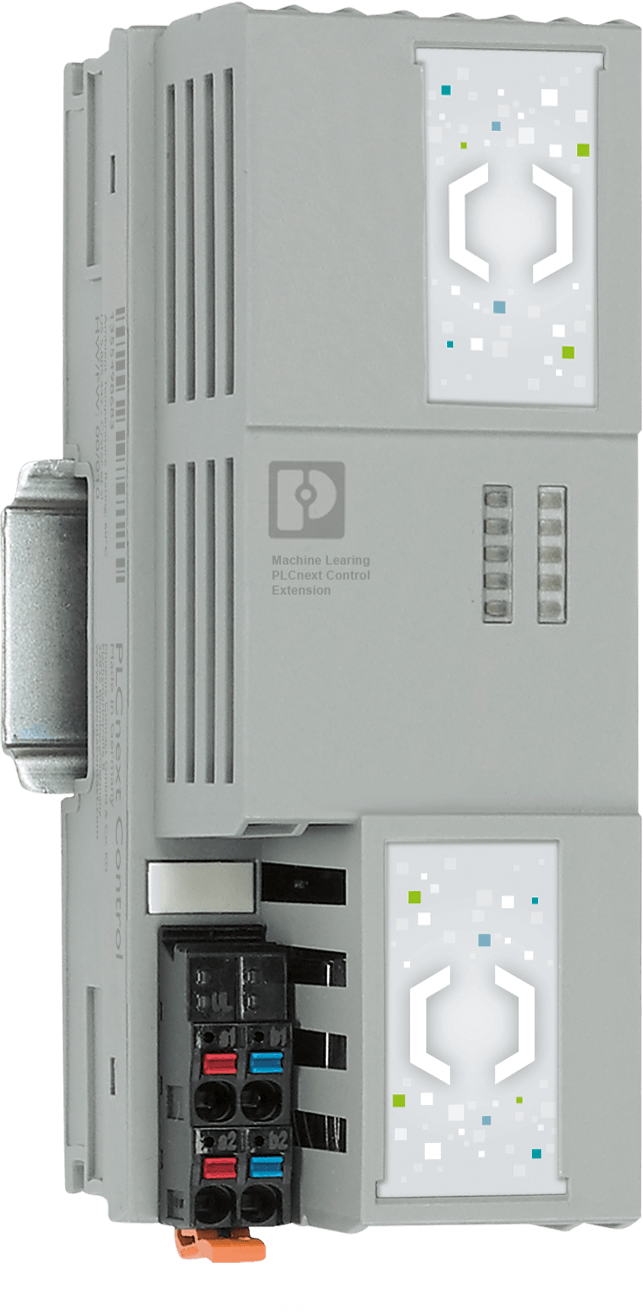

PLC function extension

Function extension on the left side of your controller

The PLCnext Control AXC F 2152 and AXC F 3152 can be functionally extended thanks to extra modules that can be added to the left of the controller. Perform AI or machine learning tasks, use an additional Ethernet interface or transform your PLCnext Control into a safety controller for safe applications up to SIL 3. Connect up to three modules to your PLC with an additional extension module and use more than one function extension. In addition, an INTERBUS and PROFIBUS master is available with which you can integrate INTERBUS or PROFIBUS remote bus devices into the station.

- Google Edge TPU ML accelerator

- 4 trillion operations per second (TOPS)

- PCIe Gen2 4 Gbit/s

- Standardized interpreters: TensorFlow Lite or AutoML

- Edge-AI: No detours via external networks

- -20°C – 55°C

- For use with AXC F 3152 only

- 2x Cortex M4

- Up to 32 PROFIsafe devices

- -25°C – 60°C

- Width: 45mm

- Approvals: UL, CUL, etc.

- Reloadable C functions

- TÜV Rheinland certified in accordance with IEC 62443-4-1 ML 3 (Full Process Profile) and IEC 62443-4-2 SL-C 2

- Additional 1Gbit MAC interface

- -25°C – 60°C

- Profinet control capability

- Security due to separated interfaces

- UL (Hazloc), CUL

- DNV/GL, LR, BV, ABS, …

- IEC Ex, ATEX

- Additional INTERBUS master

- Up to 512 devices, up to 255 remote devices, up to 126 PCP devices

- Up to 16 remote bus levels

- 4096 bit process data

- Auto detection for 500 kBit and 2 Mbit

- Ideal for retrofit applications

- PCIe extension unit

- Left side extension for up to three more devices

- Standard PCIe Gen 2 Interface

- Transfer rate: 0,5 GByte/s (4 GBit/s)

- -25°C – 60°C

- UL (Hazloc), CUL

- IEC Ex / ATEX

- DNV/GL, LR, BV, ABS, Rina, KR

- Additional PROFIBUS master

- Up to 125 supported devices

- Protocols DP-V0 and DP-V1

- Process data max. 488 bytes (244 bytes IN / 244 bytes OUT)

- Baudrate: 9,6 Kbit/s…12 Mbit/s

- -25°C – 60°C

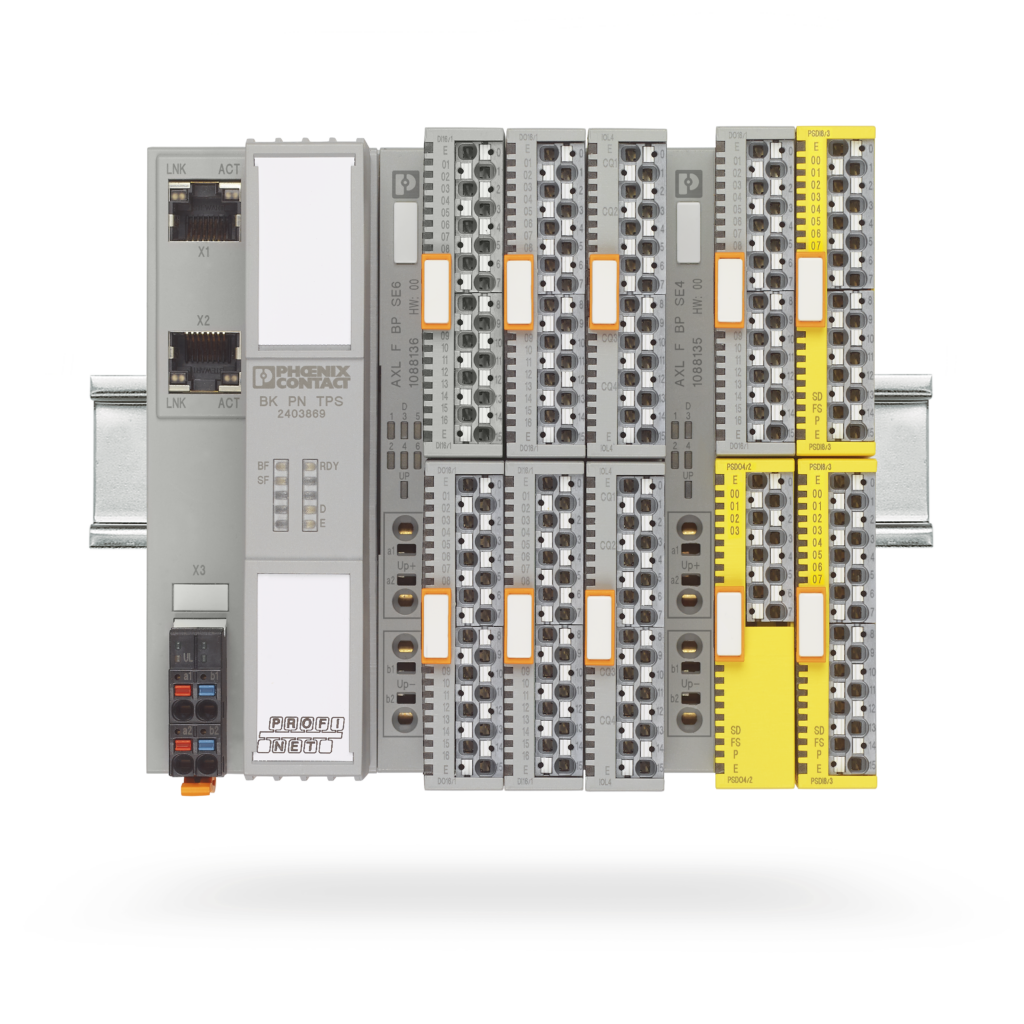

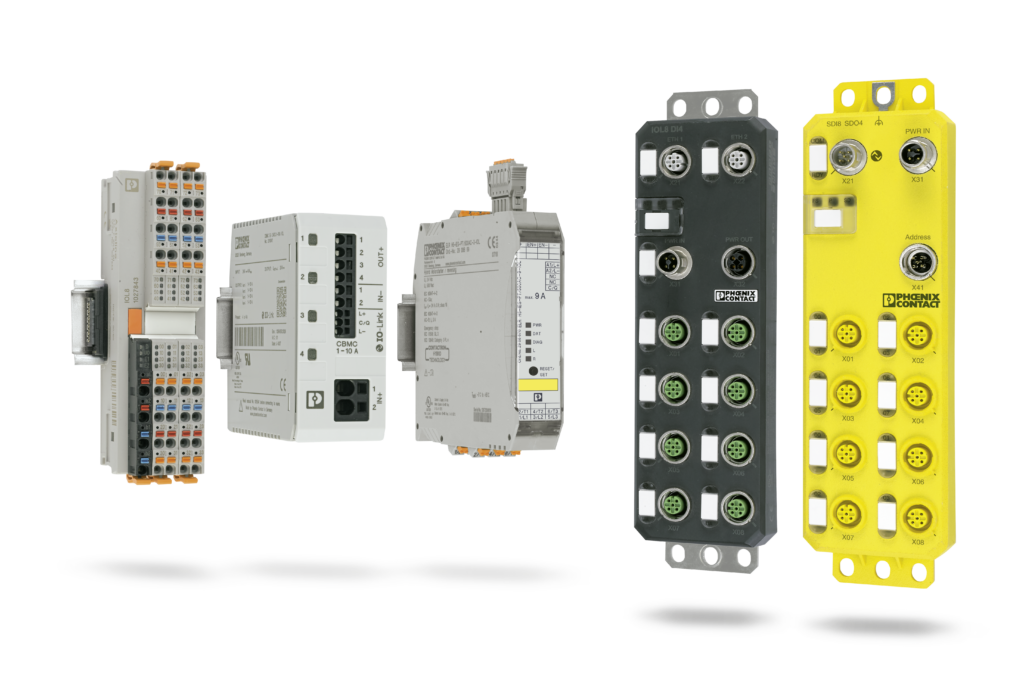

I/O-Systems

Precisely fitting the design of your automation system

due to a highly modular hardware

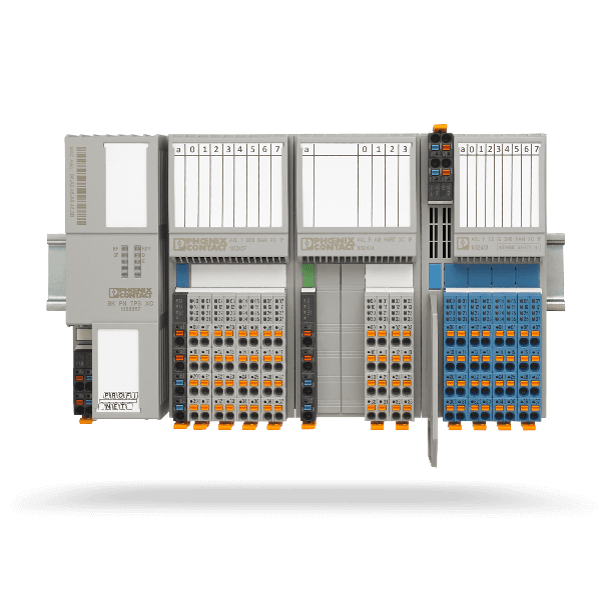

With the modular PLCnext Control AXC F 1152, AXC F 2152, and AXC F 3152 you are very flexible in your station design. Choose from a wide range of I/Os which are designed to your needs. Phoenix Contact offers Axioline Smart Elements with a most compact design and flexible slot selection. Or use robust I/Os of the Axioline F product range for harsh environments. You can even combine both I/O families with up to 63 I/O modules.

More space for you creativity

The amount of space needed for components installed in the control cabinet is becoming increasingly important. With the growing modularization of machinery, the use of the traditional control cabinet is declining. Instead, the devices are installed in small control cabinets that are integrated into the relevant machine modules. With PLCnext Control and Axioline Smart Elements you can achieve a high degree of flexibility with respect to the station structure and a wide range of function modules.

- 8 or 16 connection points

- Small footprint of 15 mm x 62 mm

- Easy handling: tool-free unlock mechanism reduces installation efforts

- -25°C – 60°C

- Perfectly integrated in PLCnext Engineer

Robust and intrinsically safe

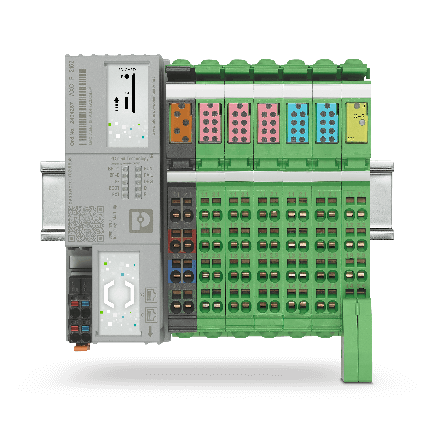

Some industries – like marine, offshore, and the process industry – have special requirements for the PLCnext Control station. The digitalization of ships in all service life phases requires new technologies and solutions that meet future requirements to operate ships more efficiently and digitally. In addition to standard signals – such as analog and digital signals – maritime and offshore applications also involve special types of data protocols which must be incorporated and processed. On the other hand, in the field of process technology and process engineering, system availability, modularization, and digitalization are key. With PLCnext Control and Axioline F you can chose the best matching hardware – even for harsh conditions.

- High speed localbus

- Very robust housing concept

- Numerous approvals

- Pluggable connectors with multiconductor connection

- Protocols DP-V0 and DP-V1

- Partly for use in EX zone 2 installations

- -25°C – 60°C (XC: -40°C – 70°C)

Reuse your legacy Inline station

We have to adjust faster and faster to new technologies, including technologies that are considered futuristic even by today’s standards. But why throw away an entire automation station if you can easily adapt it to future technologies?

- Connector for 63 Inline I/Os

- 24 PCP Devices can be used

- 4096 Bit Input / Output Data

- 20 mA current consumption

- Degree of protection IP20

- Approval: – UL, CUL – DNV/GL, LR, BV, ABS, Rina, KR

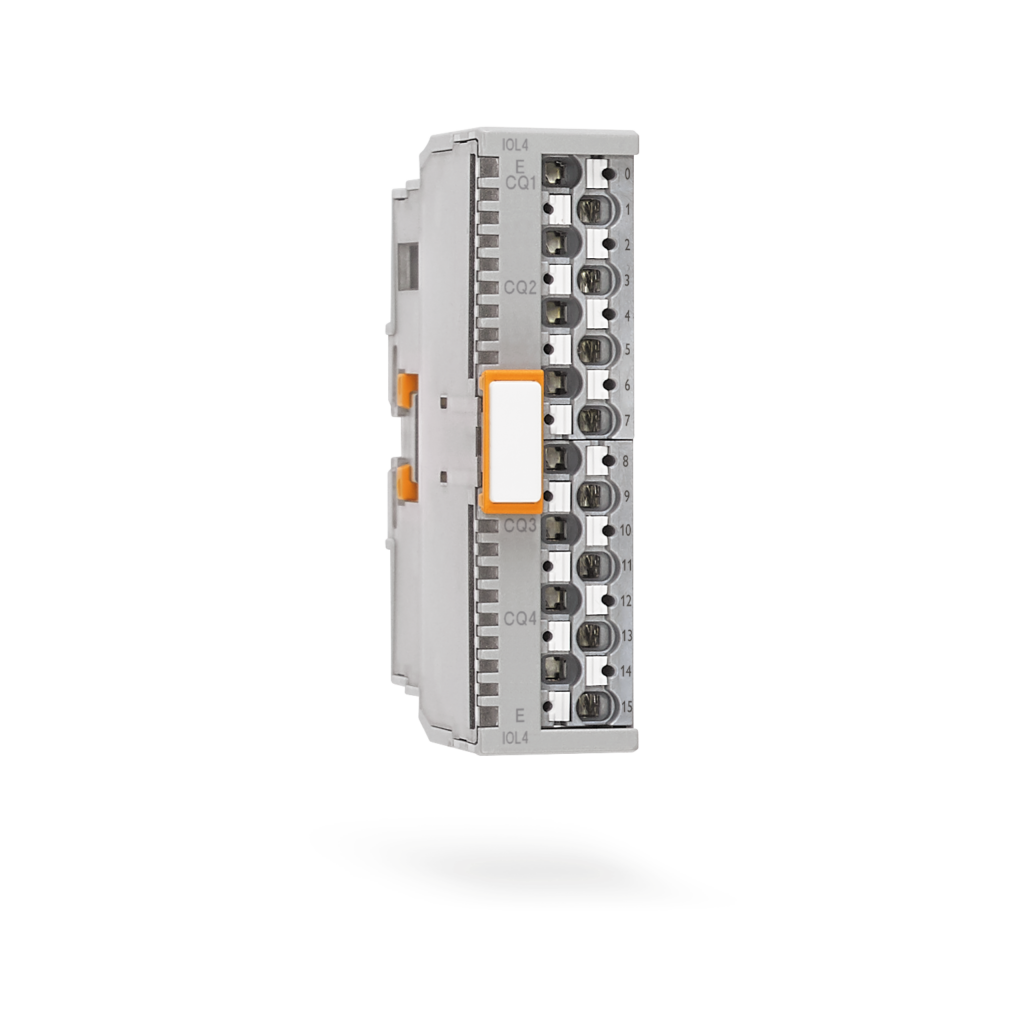

IO-Link

IO-Link is currently the fastest-growing communication standard in the field of industrial automation. The reason behind this dynamic growth is that it is standardized, open, and cost-effective. To this end, PHOENIX CONTACT offers a comprehensive IP20 and IP67 portfolio of IO-Link masters, IO-Link devices, cabling, and software which is also integrated in the PLCnext ecosystem. PLCnext Engineer offers comfortable parametrization of IO-Link devices. You can therefore ensure consistent communication all the way to the field level.

Supported communication protocols

Two options are already available as fieldbus protocols: PROFINET and EIP (Adapter Class).

Further fieldbus protocols, e.g. INTERBUS, PROFIBUS, or CAN can be realized by adding appropriate hardware components. Also these common Ethernet protocols are available: HTTP, HTTPS, SFTP, SNTP, IPsec, syslog and OPC UA. Additionally, you can easily add missing Ethernet protocols due to the open architecture of PLCnext Control. What makes PLCnext Control unique is that further function blocks can be reloaded via the PLCnext Store which is accessible to every user. Via the PLCnext Store you can download ready-made solutions or extensions of the controller or add them yourself. Examples are: MQTT, Codesys, Modbus TCP and libraries for ready-made industrial solutions. On top of that, additional runtimes can be replicated via IEC 61131 or even integrated in the firmware. You can also realize that with software from external companies. The open architecture of PLCnext Technology makes it possible.

What’s next?

PLCnext Control and Extensions

AXC F XT SPLC 3000

- Left-alignable Safety PLC extension module; communicates with up to 300 PROFIsafe devices via PROFINET or Axioline, while the integrated F-Device instance enables networking to a higher-level PROFIsafe controller

PLCnext Runtime

- OPC UA PubSub with integrated support for security

- Supports SPLC 3000

- Extended diagnostics in the Web-based Management (WBM)

- Retain for PLCnext function extensions and apps

- IPsec configuration via WBM

- OPC UA software update for Axioline stations

- Kernel update to 5.14 or higher

- OPC UA Client basic implementation