Augmented reality (AR) can make many processes in manufacturing even more efficient. Especially in complicated changeover processes or maintenance work, the technology offers high savings potential. The cost of implementation is usually still high, but the solutions are improving constantly. For an efficient rollout a flexible, powerful and open control platform in the field is recommended as a basic requirement.

Automation technology is becoming increasingly sophisticated and more intelligent. This increases efficiency in production, throughput is also increasing. At the same time, customers are demanding more individualized products, so batch sizes are becoming smaller. This in turn means that machines often must be retooled several times a day, and maintenance work is also increasing as a result. However, the highly complex machines require trained specialists to perform the work – and even they cannot do the work without manuals and circuit diagrams. Not to mention the shortage of skilled workers…

In addition, there is a simple but in practice annoying disadvantage: When maintaining or retooling machines, the famous third hand is missing because the manual has to be held somewhere. And as good as manuals are, drawings and the real machine simply drift apart, spatial thinking is required. All this costs time in the end and reduces productivity.

Process acceleration through AR

In order to limit the time required for maintenance and conversion work on machines on the one hand, and to reduce the need for highly trained specialists on the other, AR is an ideal technology with great potential for reducing the need for highly trained specialists. Augmented reality supplements the real world with higher-level virtual elements. With the help of ambient cameras and depth cameras of AR glasses, the real surfaces are reconstructed and enable the holographic representation on physical surfaces.

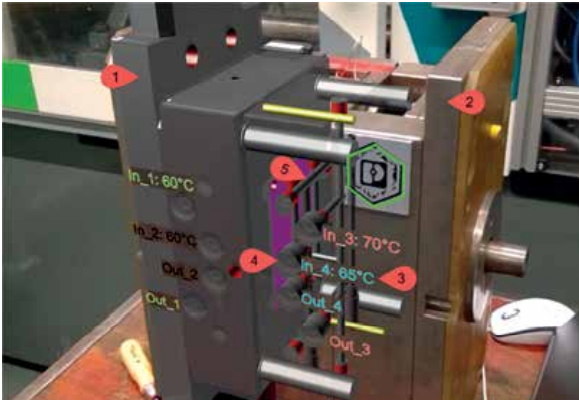

For example, AR technology recognizes an injection molding machine and its components when viewed. Thanks to the complete three-dimensional detection, information and overlays can always be displayed to match the viewing angle. Thus, when looking at the machine, the technician with the AR glasses immediately sees the current production data, any warnings or maintenance instructions, or upcoming changeover procedures. And this is where it gets interesting: In addition to show real-time information, the glasses can also look inside the machine and show the technician which components or tools need to be replaced or converted where and how. The worker can have the next work step displayed in his field of vision without having to laboriously leaf through manuals. In order to have this kind of information available, open control systems can provide the necessary transparency and availability of data from the field. In addition, this is also the key to linking established systems, current and future technologies such as AR.

Maintenance work four times faster

Much of the success of AR is due to Microsoft’s HoloLens. No other glasses have been accepted so quickly which is certainly also due to the fact that many companies are already using Microsoft platforms. For example, Mercedes-Benz uses HoloLens as a tool in its sales and technical training. Honeywell is using AR to simplify vocational training and the induction of employees, with the hope of reducing training time by around 60 percent. Phoenix Contact uses glasses in facility management for maintenance and repair. Thyssenkrupp uses augmented reality to maintain elevators. Field tests showed that maintenance work can be completed up to four times faster than before. These examples show the huge potential benefits of AR. A key factor here is the amount of time saving because the technician no longer has to spend time searching through manuals but receives targeted instructions for action – either superimposed or remotely switched on by an expert. It reduces the amount of training required and makes printed documentation obsolete. Instead of having to compare CAD drawing and the workpiece or machine, AR offers a visual, optical overlay.

Setup processes error-free and faster

Augmented Reality also enables significantly more efficiency in everyday production tasks directly on the machine. For example, the injection molds on an injection molding machine regularly must be changed to produce different article variants. For this purpose, the employee disassembles the mold and reassembles it after components have been replaced. In addition, a mold maker immediately carries out maintenance of the tool by cleaning and greasing the surfaces and checks the tightness of cooling channels. These procedures also apply to most machine tools when setup operations for other product variants are necessary.

In practice, for most production companies, the rebuild instructions are simple 2D drawings and component numbers. For untrained workers these are completely inadequate since no rebuild steps are explained. Maintenance instructions are quite often missing as well because mostly the experience of the toolmaker is relied on. Machine operators and employees on production lines are not able to rebuild or maintain tools without background knowledge, even if they all the other resources. Through the AR application, employees in an injection molding shop can carry out the rebuild and maintenance process of the mold without having any mold making knowledge. Based on expert opinions and validation tests, the process cycle of a mold rebuilds, using the example of an injection molding machine, can be reduced from two hours by 90 minutes through the use of AR. Typical errors during setup, such as the incorrect connection of temperature control channels which cost a lot of time to rectify, are also avoided in this way. The advantages of AR technology pay off in makeready processes: All the necessary documents are available directly when working on the workpiece and are always up to date, thanks to central provision, operation is intuitive, and the risk of errors is reduced with less time and effort spent searching.

Effort lies in the process of creating the data

But the introduction of AR means effort- especially the development of the application. For example, animations and 3D objects can be integrated into a game editor via CAD software, programmed for interactions and generated as an application. This method offers much freedom but requires advanced programming skills and is time-consuming. The AR applications must also have automated data interfaces to Product Data Management (PDM), Product-Lifecycle-Management (PLM) and Manufactoring Execution System (MES).

Accelerating with AR platforms

For a straightforward generation of AR applications, software developers offer preconfigured platforms such as Vuforia from PTC. The AR platform AcRoSS, funded by the ‘Smart Service Welt’, of the technology program of the Federal Ministry for Economic Affairs is intended to help provide reusable AR building blocks. This way, especially small and medium-sized enterprises should also be able to create complex AR-based services from the individual modules that are tailored to their own needs in a time- and cost-effective manner. Via the platform, all data between the AR devices used, production and logistics systems, and internal company software applications can be queried, exchanged, and networked with each other.

Connectivity on any machine

Central to the use of augmented reality in production is the simple connection of data glasses to the place where the action takes place. Accordingly, the technician needs for example, an automatic connection at the injection molding machine and access to the current production data. This provides a powerful and open control platform on the machine. The system knows all the parameters of the machine and not only knows which control tasks and batches are due in the near future but can also use data analysis to make the appropriate recommendations for maintenance procedures. An AR application must be therefore based on a relevant database in order to be able to display relevant information in real time.

Open control platform as basis

Due to the performance and openness of a modern, open ecosystem much as PLCnext Technology from Phoenix Contact, the AR connection can be implemented at any time. Thanks to the open source concept and support of the runtime environments relevant to the market, users can access the data from the controller from their favorite AR application or run the app directly on the controller. An additional industrial PC on the machine or in the control cabinet is thus unnecessary. A modern control platform thus not only acts as an interface to the field devices but also provides the connection to cloud instances and display devices such as AR glasses. Anyone who relies on these open systems – even now – is laying the foundation for AR and other promising technologies in their own company.