Sharing software applications is not (yet) common in industrial automation.

The manufacturer’s software libraries are used to develop applications themselves, but different users share virtually nothing with each other – while many benefits can be gained there. Buying functionality can be more efficient and cheaper than reinventing the wheel yourself. In addition, it provides access to applications that the user may not have been able to develop at all, due to complexity or time-to-market.

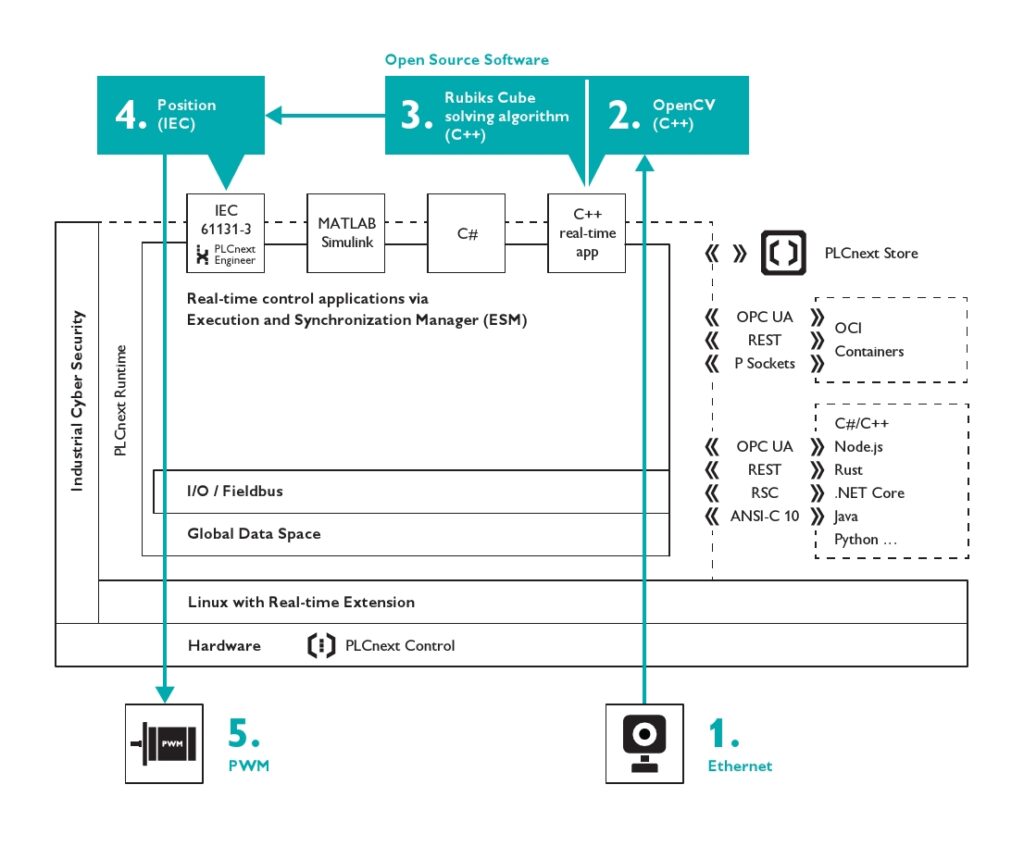

When the use of Open Source Software also becomes possible for the PLC, completely different functionalities can be added to the industrial control platform. Users will then have access to functionalities that were not possible before and for which they do not need to have the knowledge themselves.

Rubik Cube Solver with PLCnext Technology

In 2019, the estate For inspiration, we have developed an application for a Rubik Cube Solver to show these new possibilities. For this we downloaded 3D files from an open 3D print community for a 3D printer. We screwed the printed parts together and fitted them with 8 servo motors and a simple IP camera. The IP camera is connected to the PLCnext Controller via Ethernet and the servo motors are connected to the positioning modules next to the PLCnext Controller.

Besides the 3D files we have also downloaded various Open Source Software from the internet. For example, with an OpenCV library we can analyse the images from a simple IP camera and recognize the colour pattern of the Rubik Cube. With a Rubik Cube Algorithm, also from the internet, we know how to solve the puzzle. Finally, a classic PLC program moves the servo motors to the correct positions.

Previously, this could only be achieved by a classic PLC in combination with either an industrial PC or an advanced, expensive camera. Thanks to the PLCnext Technology, this application can now be realised with 1 industrial control platform.